Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Original price was: ₹1,000.₹749Current price is: ₹749.

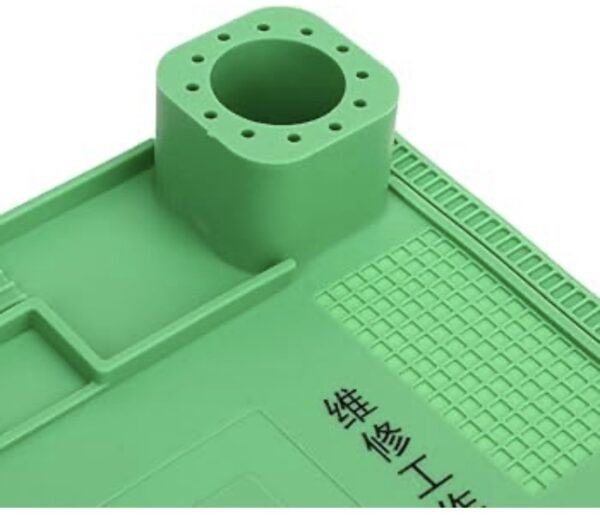

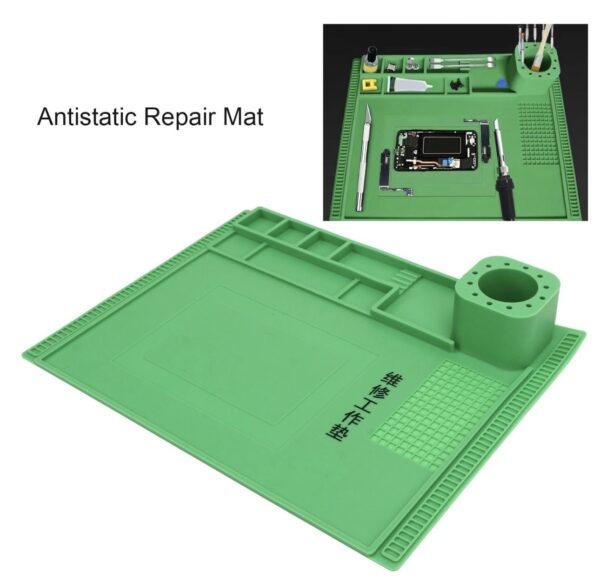

Silicone Repair Pad, 40x30cm Multifunctional Heat Insulation Good Resilience Soldering Mat for Electronics Maintenance are specialized work surfaces designed to enhance the efficiency and safety of soldering and repair tasks, particularly in the realm of electronics. Composed primarily of high-quality silicone, these pads boast considerable flexibility and durability, which makes them a valuable addition to any technician or hobbyist’s toolkit. Measuring 40x30cm, they provide ample space for intricate work and component arrangement while ensuring the protection of underlying surfaces, such as desks or tables.

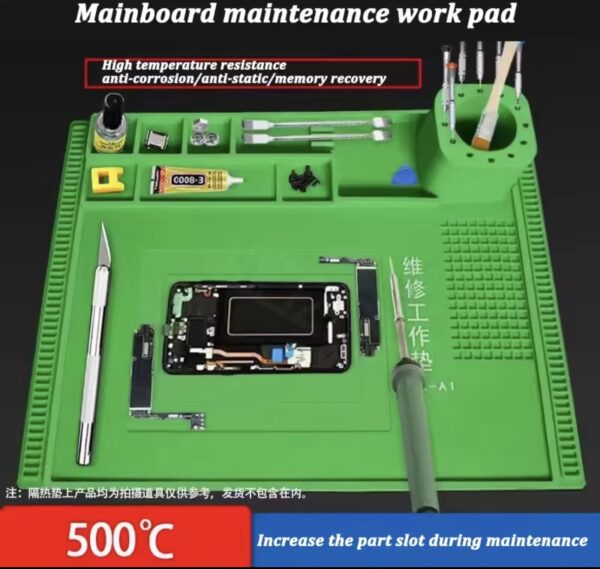

One of the most significant advantages of silicone repair pads is their multifunctional properties. Unlike traditional work surfaces, which may harm electronic components or be susceptible to damage from heat or solder, silicone pads offer a non-stick, heat-resistant surface. This feature allows for the safe handling of solder and tools, reducing the risk of burns and accidental damage to sensitive components. Moreover, many silicone pads come equipped with built-in compartments and grids for organizing small parts, enhancing productivity by keeping the workspace tidy and efficient.

Commonly used in electronics maintenance, silicone repair pads serve as an ideal base for a variety of tasks, including soldering, desoldering, and assembling electronic devices. Their adherence to the natural principles of heat management further distinguishes them; they are crafted to withstand high temperatures associated with soldering, ensuring that the pad remains intact and effective even under demanding conditions. In addition, silicone’s inherent properties help to prevent components from sliding or rolling off the work surface, which is a frequent issue experienced with traditional pads. Overall, silicone repair pads are an essential component for anyone involved in electronics repair, significantly enhancing the soldering experience through careful design and thoughtful functionality.

The 40x30cm silicone repair pad is designed to meet the demanding needs of electronics enthusiasts and professionals alike. One of its most significant attributes is its exceptional heat insulation properties. Crafted from high-quality silicone material, the pad effectively intercepts and dissipates heat, ensuring that both the surface underneath and the surrounding area remain protected during soldering tasks. This feature mitigates the risks associated with overheating components, thus enhancing the safety of your work environment.

Another key characteristic of the silicone repair pad is its good resilience. This means that the pad can withstand repeated use without degradation, maintaining its shape and functionality over time. It is engineered to absorb impacts, which helps in safeguarding delicate electronic components from scratches and damage. The durability of the pad not only provides long-term value but also contributes to more efficient soldering processes, as users can rely on a consistent work surface.

The anti-slip surface of the silicone repair pad is meticulously designed to prevent movement during various tasks. This feature ensures that your tools and components remain securely in place, allowing for precision during soldering. It significantly reduces the likelihood of accidents caused by slipping materials, providing a stable platform for detailed work. Additionally, the pad’s ability to withstand high temperatures makes it ideal for professional soldering applications, where extreme heat is a common aspect of the job.

In conclusion, the 40x30cm silicone repair pad excels in heat insulation, resilience, anti-slip capabilities, and temperature tolerance. These features combine to create an essential tool for anyone involved in electronics maintenance, making it a crucial addition to any soldering setup.

Silicone repair pads have gained significant attention in the field of electronics maintenance, primarily due to their multifaceted advantages. One of the foremost benefits is the enhanced precision they offer during soldering tasks. The pads are designed to withstand high temperatures, ensuring that they do not degrade or lose their integrity even under intense heat. This durability allows users to work with confidence, as they can focus on their soldering techniques without worrying about damaging the pad or surrounding components.

In addition to precision, silicone repair pads serve as a protective barrier for delicate electronic components. During the soldering process, the risk of accidental drops or spills is always present. These pads provide an anti-static surface that helps minimize the risk of electrostatic discharge, a common threat to sensitive electronics. Consequently, utilizing a silicone repair pad can significantly reduce the chances of component damage, ultimately leading to better project outcomes.

Another noteworthy advantage of silicone repair pads is the ease with which they allow for cleanup. As DIY enthusiasts and professionals work on their projects, soldering tasks can cause minor spills of flux, solder, and other substances. Silicone pads are inherently non-stick, making it simple to wipe away residues and keep the workspace organized. This ease of cleanup not only saves time but also helps maintain a clean and efficient working environment.

Moreover, the use of silicone repair pads enhances overall efficiency during both DIY projects and professional electronics maintenance tasks. By providing an organized surface with designated compartments for components, users can easily access the tools they need, streamlining the workflow. This organization contributes to a more efficient working process, making the experience considerably more enjoyable for both novice and experienced users alike.

Using a silicone repair pad effectively requires an understanding of its setup, maintenance, and storage. First and foremost, ensure that your work surface is clean and dry before placing the silicone pad. This prevents any contaminants from adhering to the sensitive components you may be working on. For optimal results, choose a flat, stable area free from vibrations, which may disrupt delicate soldering tasks.

Silicone repair pads are particularly beneficial for various electronics work; therefore, customize your setup based on the project at hand. For example, when working with small components, consider utilizing the pad’s built-in compartments to organize screws, resistors, and other parts. This minimizes the risk of losing essential items and maximizes your efficiency. If working with heat sensitive components, ensure the pad’s surface is adequate for the task. Most silicone pads are heat-resistant, but staying within the temperature limits is critical to avoid damage.

Another essential aspect of using silicone repair pads is maintaining their surface. Regularly clean the pad with a damp cloth, especially after projects that involve solder. Non-abrasive detergents can be used to remove more stubborn residues; however, avoid using solvents that may degrade the silicone material. Additionally, inspect the pad routinely for signs of wear or damage, as any cracks can compromise its safety and functionality during use.

When not in use, store your silicone repair pad in a cool, dry place away from direct sunlight. This prevents fading and extends the life of the silicone material. Proper use and maintenance of your silicone repair pad are crucial for prolonging its lifespan, protecting your components, and ensuring an efficient soldering experience.

In the realm of electronics maintenance and soldering, a silicone repair pad stands out as an essential tool that every enthusiast should incorporate into their toolkit. The benefits of using a silicone repair pad are manifold, contributing to both improved efficiency and enhanced safety during soldering tasks. These pads are designed to withstand high temperatures, provide a non-slip surface, and are resistant to various chemicals, making them particularly suitable for soldering applications.

One of the primary advantages of silicone repair pads is their ability to simplify organization while working on intricate electronic components. With multiple compartments for small parts, they help keep components organized and readily accessible, significantly reducing the risk of misplacing vital pieces during a project. Additionally, their flexibility and resilience allow for easy cleanup, as spills can be wiped away without damaging the surface, unlike traditional workspaces.

Moreover, silicone repair pads contribute to the overall safety of the soldering process. The heat-resistant nature of silicone minimizes the risk of burns and protects the work surface from hot solder and soldering irons. This is especially important for those frequently engaged in hands-on electronics work, where unforeseen accidents can occur if proper precautions are not taken.

Incorporating a silicone repair pad into your electronics maintenance toolkit not only enhances your soldering experience but also ensures a safer working environment. The combination of convenience, organization, and safety makes it a worthy investment for both novice and experienced solderers alike. Ultimately, adding a silicone repair pad will enable enthusiasts to focus more on their craft and less on managing the various challenges that arise during soldering tasks, leading to a more enjoyable and productive experience.

More Products : https://gsmtoolsindia.com/

Official Website : https://www.mechanichk.com/

| Weight | 0.4 kg |

|---|

Reviews

There are no reviews yet.