Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Original price was: ₹30.₹25Current price is: ₹25.

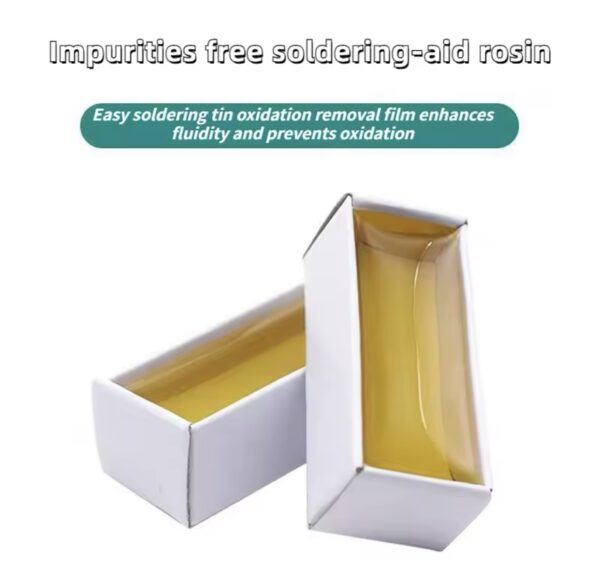

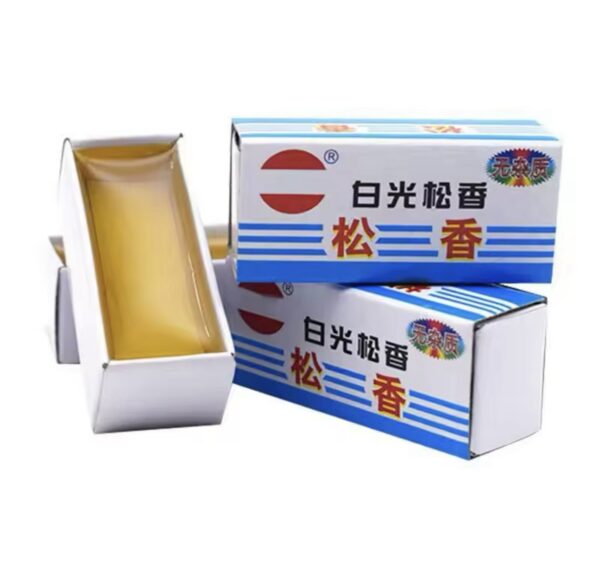

10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding serve a crucial function in the field of electronics, providing a means to create electrical connections between various components. Among the diverse soldering materials available, 10g soldering tin stands out for its effective use in both professional and amateur applications. Soldering requires the proper selection of materials to ensure strong, reliable joints that can endure thermal and mechanical stress, and tin-based solder is frequently utilized for this purpose. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

The primary skill associated with soldering involves melting and bonding these materials to create electrical circuits. Tin is a key component in most solder alloys, offering excellent conductive properties and a relatively low melting point, which allows for easier application. The 10g designation indicates the weight of the solder, making it a convenient option for various repair jobs or projects. Its manageable size provides hobbyists and technicians with a practical quantity, minimizing waste while allowing flexibility for intricate work. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

In addition to the tin, rosin flux plays an essential role in the soldering process. Flux serves to clean the surfaces of the materials being joined, aiding in the prevention of oxidation that could impede a strong bond. The combination of 10g soldering tin and appropriate rosin flux enhances the efficiency of soldering tasks, ensuring that the connections achieved are durable and conductive. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Understanding the various forms of solder is also vital for successful repairs. While traditional solder usually contains a mix of lead and tin, lead-free variants are increasingly preferred due to health and environmental concerns. Options such as silver solder and high-temperature alloy solder provide additional choices for specialized applications. By selecting the appropriate solder, technicians can optimize performance in their electronic repair endeavors. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Soldering tin comes in various types, each designed for specific applications and manufacturing requirements. The most common type used in electronic repairs is soft solder, which is primarily an alloy made of tin and lead, although lead-free alternatives are increasingly popular due to health and environmental considerations. Soft solder typically comprises a composition ratio of approximately 60% tin to 40% lead, though variations exist, particularly in the context of the 10g rolls frequently utilized by hobbyists and professionals alike. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

The properties of soft solder make it especially suitable for electronic repairs. Notably, it has a relatively low melting point, usually around 180°C to 190°C, which allows for easy application with a soldering iron. This low melting temperature reduces the risk of damaging sensitive electronic components. Additionally, the flow characteristics of soft solder ensure a smooth application, effectively bridging connections between components. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

In contrast, other types of solder, such as hard solder, use higher melting point materials. These include various combinations of metals like silver, copper, and zinc, making them ideal for applications requiring stronger joints, such as plumbing or metal fabrication. The higher melting points (usually above 450°C) mean that hard solder isn’t suitable for delicate electronics, as it can easily damage components during the soldering process. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Another alternative is lead-free solder, which often employs a blend of metals such as tin, copper, and silver. While these solders are more environmentally friendly, they generally have a higher melting point and can result in more challenging soldering applications. Understanding the different types of soldering tin, particularly soft solder and its variants, is essential for selecting the most appropriate material for any electronic repair task. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Rosin flux is a crucial component in the process of soldering, particularly in electronic repairs. It serves multiple purposes that collectively enhance the quality and reliability of solder connections. Primarily derived from natural colophony, rosin flux is a type of adhesion promoter that facilitates the bonding of metal surfaces during the soldering process. Its chemical properties allow it to effectively prevent oxidation, which is a significant concern when working with metals like copper and tin. By eliminating oxidation, rosin flux ensures that solder can flow smoothly onto the surface, creating a strong joint. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

One of the key advantages of using rosin flux in soldering is its ability to improve the overall quality of solder joints. Without flux, solder might not adhere properly to metal surfaces, potentially leading to weak connections. As the solder flows, rosin flux assists in cleaning the metal surface, removing any impurities that could hinder adhesion. This results in a durable bond that is less prone to failure over time, which is particularly important in electronic applications where reliability is paramount. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Furthermore, rosin flux is often categorized into different types, including neutral and activated fluxes. Neutral rosin flux, which is more suitable for electronic applications, does not leave corrosive residues that could damage sensitive components. On the other hand, activated fluxes may provide stronger cleaning action but can leave residues that necessitate post-solder cleaning. For electronics, using neutral rosin flux is generally recommended as it protects against oxidation while being less harsh on delicate circuitry. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

In summary, the role of rosin flux in soldering is integral to achieving high-quality, reliable solder joints. Its properties effectively prevent oxidation and enhance metal flow, making it an essential material in electronic repairs. Understanding the differences between types of flux can further aid in selecting the best option for specific soldering tasks. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

To achieve effective soldering with 10g soft solder, it is essential to start with a well-prepared workspace. Ensure that the area is clean, well-lit, and free from clutter, allowing for easy access to tools and materials. Gather all necessary equipment, including your soldering iron, soldering stand, sponge for cleaning, and the 10g soft solder, as well as safety goggles and a fume extractor if available. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Once everything is assembled, it is important to set the soldering iron to the correct temperature. A standard temperature range for soldering with 10g soft solder is around 350°C (662°F). Too low a temperature may lead to inefficient melting of the solder, while too high a temperature can cause damage to electronic components. Allow the soldering iron to reach the desired temperature before starting the soldering process. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

When using the soldering iron, it is crucial to employ the right technique. First, ensure that the tip of the iron is clean and tinned – this promotes better heat transfer and solder flow. To solder a joint, briefly heat the connection point on the circuit board with the soldering iron, then feed the 10g soft solder into the joint. Remove the solder and the soldering iron simultaneously, allowing the solder to cool and solidify for a strong connection. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Safety precautions should also be prioritized. Always wear safety goggles to protect your eyes from potential splashes of molten solder. Additionally, work in a well-ventilated area to minimize the inhalation of any fumes released during soldering. It is advisable to keep a damp sponge nearby to regularly clean the soldering iron tip, which can enhance the tool’s performance. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Regular maintenance of the soldering iron is vital for effective use. After each soldering session, turn off the soldering iron and allow it to cool down. Clean the tip with a brass wool cleaner or wet sponge to remove any oxidized solder and build-up, which can hinder efficient soldering. Proper care will extend the life of your soldering iron and ensure consistent performance. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

The quality of soldering tin plays a critical role in electronic welding, particularly in high-stakes applications where reliability is paramount. High-purity soldering materials ensure excellent electrical conductivity and mechanical strength in solder joints. Impurities in soldering tin can significantly hinder performance, leading to issues such as cold solder joints, which are weak and prone to failure. These defects can adversely affect the longevity and functionality of electronic devices, making it essential to utilize high-purity soldering tin for reliable repairs. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

Identifying high-purity soldering materials is crucial for achieving optimum results in electronic repairs. When selecting solder, one should examine specifications provided by manufacturers. Look for solder that contains a high percentage of tin—with a minimum tin content of 95% being advisable. Additionally, soldering tin that incorporates lead can be advantageous for certain applications, though it is important to consider regulations regarding lead use in specific countries and industries. Selecting rosin flux that is designed for high-temperature applications can further enhance the soldering process, as it helps to clean oxidized surfaces, improving solder adhesion. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

The application of 10g soldering tin is particularly beneficial for intricate electronic repairs, where precision is required. This soldering material not only provides excellent flow characteristics but also allows for efficient heat transfer during the welding process. Higher-quality solder improves the integrity of the solder joint, which is vital for circuit boards in consumer electronics, telecommunications, and medical devices. By using high-purity soldering materials, technicians ensure a robust connection that is less likely to degrade over time, thereby enhancing the overall performance and longevity of the device involved. 10g Soldering Tin Material Paste Rosin Soldering Iron Soft Solder Repair Fluxe Neutral Rosin Block High Purity Electronic Welding

More Products : https://gsmtoolsindia.com/

| Weight | 0.01 kg |

|---|

Reviews

There are no reviews yet.