Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Original price was: ₹300.₹149Current price is: ₹149.

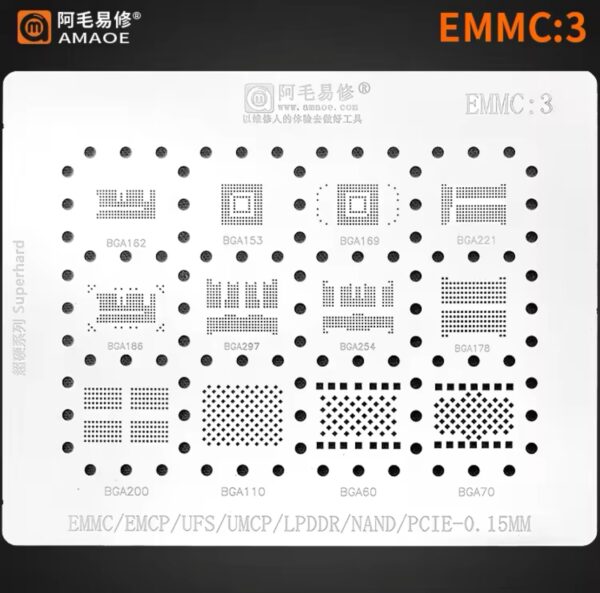

The AMAOE EMMC-3 stencil represents a significant advancement in the assembly process of various memory technologies, including EMMC, EMMC-P, UFS, UMC, LPDDR, and NAND. This innovative stencil is specifically designed to enhance the precision and efficiency of solder paste application during the manufacturing of memory modules. One of the key features of the AMAOE EMMC-3 stencil is its high-precision aperture design, which ensures optimal solder deposit for different memory chip configurations. This precision is crucial, as even minor discrepancies in solder application can significantly impact the performance and reliability of the final product. AMAOE EMMC-3 STENCIL

Moreover, the stencil is engineered using advanced materials that contribute to its durability and long operational life. These materials resist wear and tear, maintaining consistent quality in the solder paste application over extensive production runs. The AMAOE EMMC-3 stencil also exhibits excellent thermal stability, which is critical during the reflow soldering process. This stability ensures that the stencil maintains its shape and functionality under varying temperatures, thereby supporting a stable assembly environment. The applications of the AMAOE EMMC-3 stencil extend beyond traditional memory assembly. It is versatile enough to be employed in industries such as consumer electronics, automotive, and telecommunications, where high-performance memory technologies are essential. By facilitating precise soldering techniques, the stencil plays a vital role in reducing production defects, thus enhancing overall product reliability. As the demand for advanced memory solutions continues to grow, the AMAOE EMMC-3 stencil stands out as a key component in driving the evolution of memory technology in modern devices. AMAOE EMMC-3 STENCIL

Utilizing the AMAOE EMMC-3 stencil in assembly processes for devices relying on EMMC, EMMC-P, UFS, UMC, LPDDR, and NAND memory types requires a well-structured approach to ensure optimal performance. The first step involves thorough preparation before beginning the soldering process. It is crucial to clean the stencil and the PCB surface to remove any residual materials that could disrupt adherence. Additionally, verify that the stencil’s alignment marks correspond accurately with those on the PCB to facilitate precise placement.

Proper alignment techniques are paramount. Position the stencil directly over the solder pads, ensuring that the openings cover the pads fully. Employ the use of a stencil holder to maintain stability during solder paste application, which aids in achieving an even spread. When applying solder paste, a controlled motion is necessary—using a squeegee with appropriate pressure across the stencil will help fill the openings uniformly. The use of a suitable solder paste ratio is essential to avoid issues such as insufficient coverage or excessive paste that can lead to bridging.

Common challenges when using the AMAOE EMMC-3 stencil may include misalignment and insufficient paste coverage. To troubleshoot these issues, it is advisable to double-check alignment markers and assess the stencil surface for any obstructions. Furthermore, inspection post-application is vital. Leveraging magnification tools can help identify potential defects before proceeding to the next steps in the assembly process.

Finally, maintaining the stencil is critical for sustaining its longevity and performance. Regular cleaning after each use, along with proper storage away from direct sunlight and excessive humidity, will ensure that the stencil remains in optimal condition. By adhering to these best practices, users can effectively utilize the AMAOE EMMC-3 stencil, thereby enhancing the overall efficiency of their assembly operations.

Utilizing the AMAOE EMMC-3 stencil in assembly processes for devices relying on EMMC, EMMC-P, UFS, UMC, LPDDR, and NAND memory types requires a well-structured approach to ensure optimal performance. The first step involves thorough preparation before beginning the soldering process. It is crucial to clean the stencil and the PCB surface to remove any residual materials that could disrupt adherence. Additionally, verify that the stencil’s alignment marks correspond accurately with those on the PCB to facilitate precise placement.

More Products : https://gsmtoolsindia.com/

Official Website : https://www.mechanichk.com/

| Weight | 0.01 kg |

|---|

Reviews

There are no reviews yet.