Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

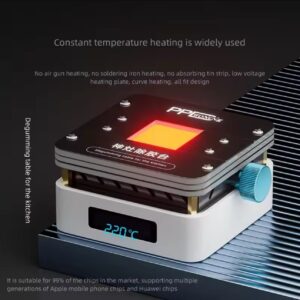

Original price was: ₹2,500.₹1,899Current price is: ₹1,899.

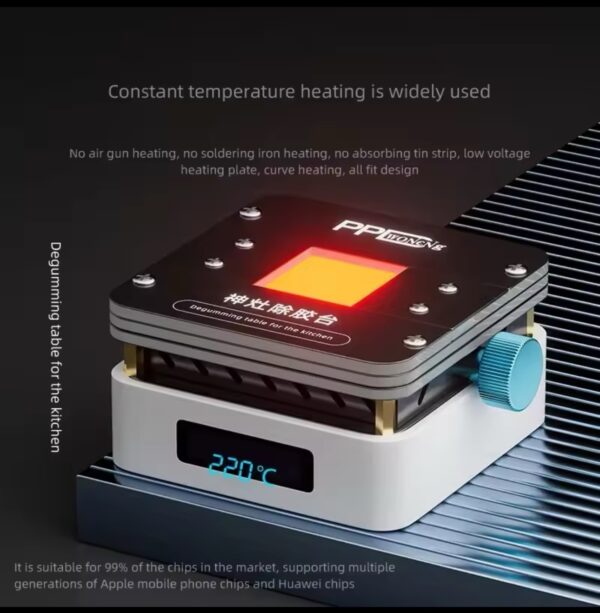

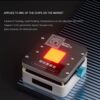

PPD CPU Heating Platform represent a revolutionary advancement in the realm of mobile phone PCB repair. These sophisticated systems utilize a specialized mode of heating that is particularly effective for achieving optimal repair results on delicate motherboards. A crucial aspect of PPD technology is its ability to deliver precise, short bursts of power, which leads to rapid yet controlled heating of specific areas, enabling technicians to efficiently target components without causing damage to surrounding elements. PPD CPU Heating Platform

Key components of PPD platforms typically include a high-frequency power supply, a heating element, and advanced temperature sensors. The power supply generates the pulsed power signal while the heating elements convert this signal into heat. Temperature sensors play a pivotal role by providing real-time feedback, thereby allowing for precise temperature control. This dynamic allows for uniform heat distribution, which is essential when resetting solder connections or removing adhesive materials utilized in the soldering process. PPD CPU Heating Platform

When compared with traditional heating methods such as hot air guns or infrared heaters, PPD technology offers several advantages. Firstly, it reduces the risk of overheating and damaging sensitive components, as the finely-tuned heating profiles restrict excessive thermal exposure. Additionally, the efficiency of PPD systems leads to quicker repair times, minimizing downtime for technicians. As a result, repairs can be conducted with higher throughput and the reliability required in commercial settings. PPD CPU Heating Platform

There is a variety of PPD platforms currently available in the market, each designed with different features and capabilities. When selecting the most suitable unit for specific repair needs, it is essential to consider factors such as heating capacity, user interface, and compatibility with various PCB configurations. Understanding these nuances can aid in making an informed decision, ultimately enhancing the repair process. PPD CPU Heating Platform

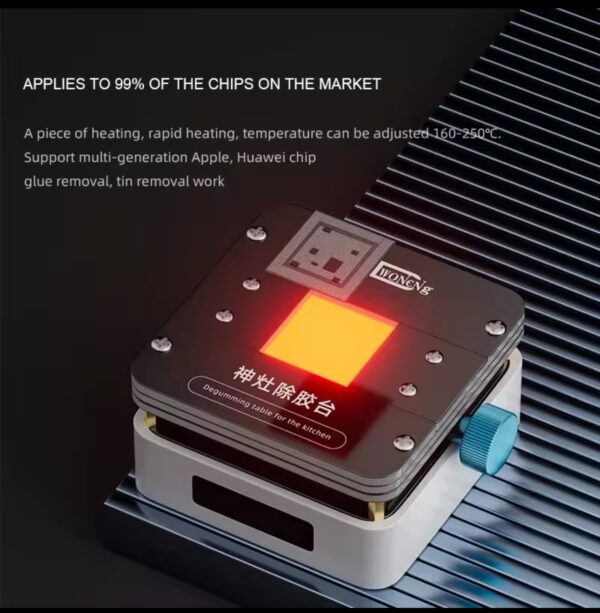

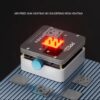

The use of PPD (Precision Preheat Device) CPU heating platforms has become integral in mobile phone PCB repair, specifically for the effective removal of glue and solder from motherboards. This section will provide an overview of the practical techniques for utilizing PPD systems to achieve optimal results in such repairs.

To begin, it is crucial to prepare the motherboard adequately before commencing any repair work. The first step involves cleaning the board’s surface to eliminate any dust or debris, which can hinder the effectiveness of the heating process. Once the board is clean, a detailed inspection should be conducted to identify the specific areas where glue and solder need to be removed, paying particular attention to components like the BGA (Ball Grid Array).

The next step is to set up the PPD system. Ensure that the heating elements are positioned correctly over the area requiring heat application. It is advisable to gradually increase the temperature, monitoring the board closely to prevent overheating, which can damage sensitive components. Typically, a temperature range of 100-150°C is sufficient for softening most adhesives and solder.

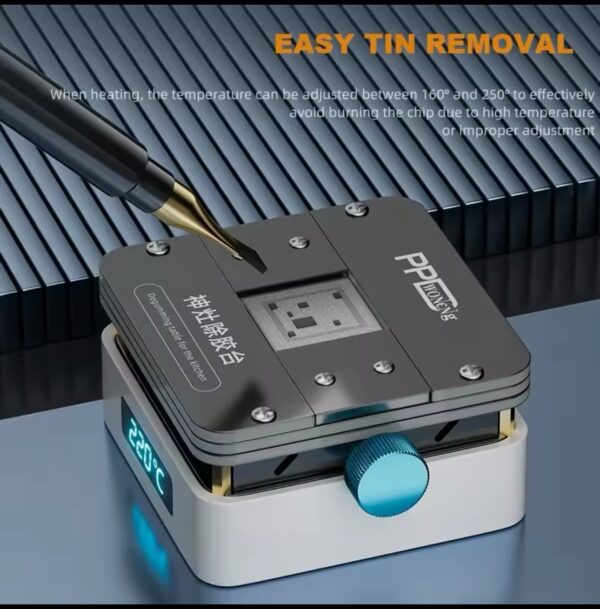

After achieving the desired temperature, use a suitable tool to gently lift and remove the softened glue and solder. Tools such as tweezers or a heat gun may be necessary, depending on the consistency of the materials. If a BGA component is being removed, careful attention must be given to avoid damaging the pads on the PCB.

During the removal process, common issues like overheating or incomplete removal may arise. If overheating occurs, promptly lower the temperature and allow the board to cool down before proceeding. If the glue or solder does not remove easily, consider reapplying heat or using a solvent specifically designed for electronic repairs.

Finally, always adhere to safety protocols and utilize appropriate protective equipment to ensure a safe working environment. This includes wearing gloves, goggles, and a heat-resistant apron to safeguard against burns or exposure to harmful substances.

More Products : https://gsmtoolsindia.com/

Official Website : https://www.mechanichk.com/

| Weight | 0.2 kg |

|---|

Reviews

There are no reviews yet.