Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

₹260 Original price was: ₹260.₹149Current price is: ₹149.

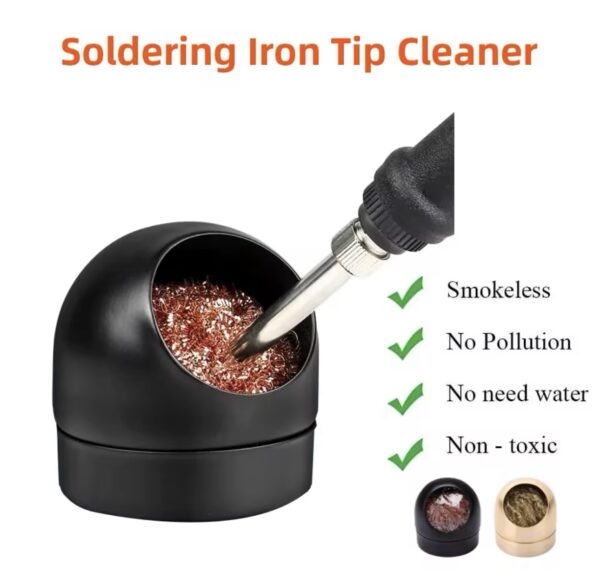

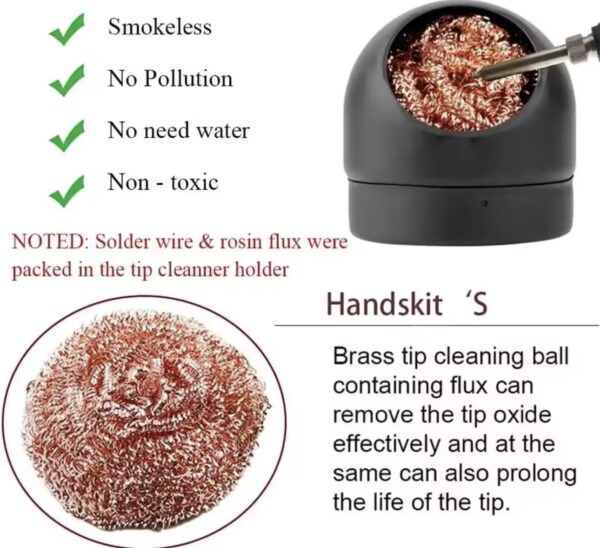

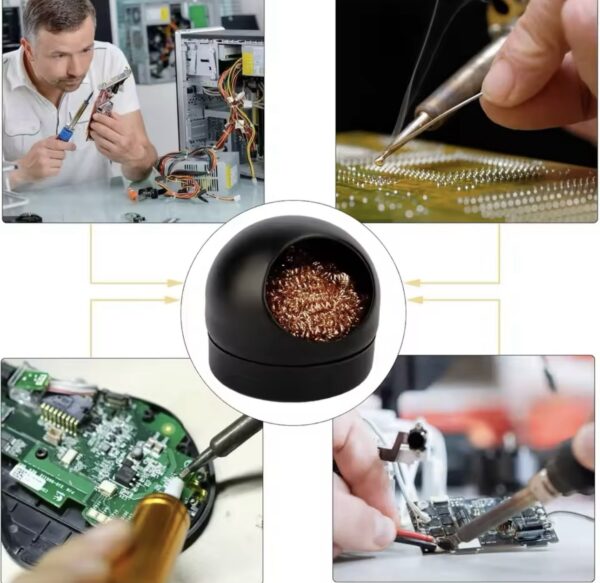

Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover designed to maintain the cleanliness and functionality of soldering tips. These cleaners play a crucial role in the soldering process, as a clean tip is vital for achieving high-quality solder joints. When soldering, the tip can become contaminated with oxidized solder, flux residues, and other debris, which may hinder the heat transfer capabilities of the soldering iron. This is where tip cleaners come into play, ensuring optimal performance by keeping the tip clean and free of obstruction. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Maintaining a clean soldering tip not only enhances performance but also extends the lifespan of the soldering iron. A well-maintained tip transfers heat more efficiently, leading to better solder joints and allowing for smoother application of solder. Neglecting to clean the tip can result in poor adhesion, weak connections, and increased wear on the iron itself, ultimately leading to a costly replacement. Therefore, using an appropriate soldering iron tip cleaner is an investment in the longevity and efficacy of the tool. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

There are various types of soldering iron tip cleaners available to suit different preferences and requirements. Cleaning balls, for instance, are made of brass and provide a gentle yet effective means of removing debris without damaging the tip. In contrast, mesh filters allow for a more passive cleaning method, where the tip is wiped against the mesh to remove excess solder and contaminants. Additionally, metal wire stands offer a functional cleaning surface while also serving as a convenient resting place for the hot soldering iron. Each of these options presents unique advantages, and selecting the right cleaner can ultimately lead to an improved soldering experience. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Choosing the right soldering iron tip cleaner is crucial for maintaining an efficient working environment while soldering. Various types of tip cleaners are available, each with unique characteristics and benefits. The three most common types include traditional sponges, brass cleaning balls, and wire mesh filters. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Traditional sponges are perhaps the most familiar soldering iron tip cleaners. Typically made from cellulose or other absorbent materials, these sponges are designed to be moistened before use. Users can simply wipe their soldering iron on the sponge to remove oxidation and solder residues. One significant benefit of sponges is their availability; they are inexpensive and can be easily replaced. However, they do require regular cleaning and maintenance, as the sponge can become laden with debris over time, which may affect its efficiency. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

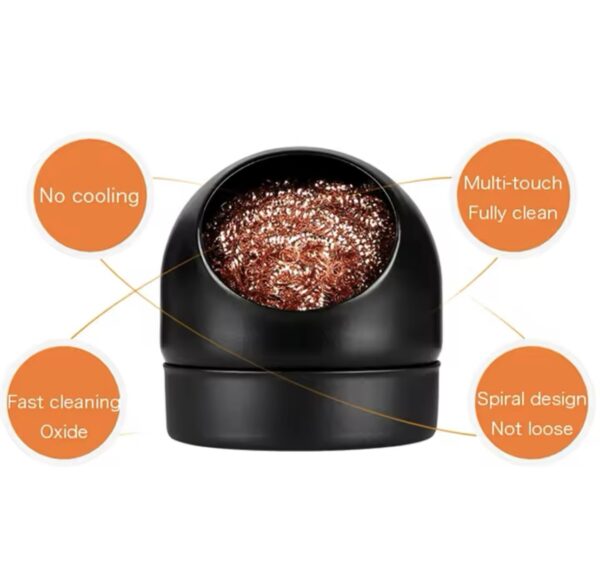

Brass cleaning balls provide a more advanced option. These consist of tightly coiled brass strands that quickly remove dirt and oxidation from the soldering tip without the need for water. This method is effective as it avoids thermal shock that can occur with wet sponges, as brass does not retain moisture. Another advantage is that brass cleaning balls do not deteriorate over time, offering a longer lifespan compared to traditional sponges. However, they can sometimes leave tiny metal particles on the tip, necessitating an additional wiping before soldering. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Lastly, wire mesh filters are also widely used. They are made from stainless steel or other durable materials and can be very efficient in removing the burnt flux and oxidation. Like brass cleaning balls, wire mesh filters do not require water and can help preserve the soldering iron’s tip temperature. However, they might not be as effective at cleaning as sponges or brass, depending on the type of residues present on the tip. Ultimately, choosing between these types of soldering iron tip cleaners depends on personal preference, soldering technique, and specific cleaning needs. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Using soldering iron tip cleaners effectively requires an understanding of the specific cleaning tools available and the proper techniques for their use. Soldering tip cleaners come in various forms, including brass cleaning balls, sponges, and dedicated cleaning solutions. Each has its unique application process, but the core goal remains the same: to maintain a clean and efficient soldering tip. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

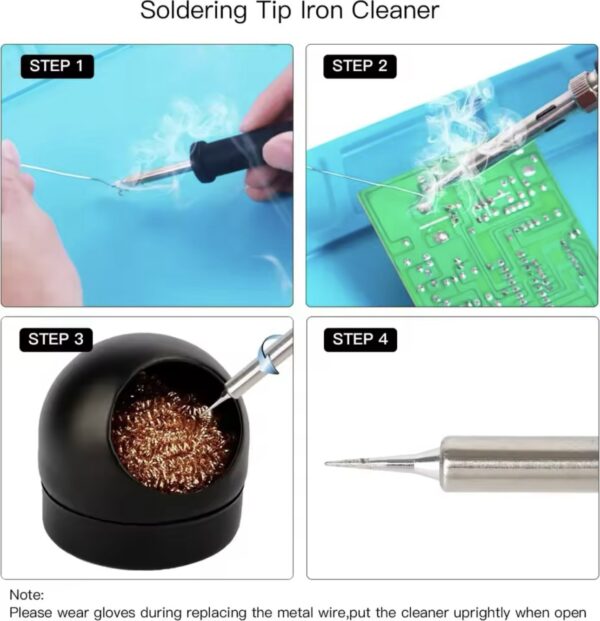

Begin by ensuring that your soldering iron is at the appropriate temperature before cleaning. For brass cleaning balls, it is recommended to heat the soldering iron to around 350°C (662°F). This temperature allows the solder to melt slightly during cleaning, ensuring that any residual solder and debris are effectively removed. Once the soldering iron is hot enough, gently tap it against the brass cleaning ball. The brass material will remove oxidation and unwanted solder without damaging the tip. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

When using a damp sponge as a cleaning method, wet the sponge and shake off excess water. The soldering iron should also be heated to a similar temperature of 350°C. Carefully wipe the tip against the moist sponge to remove any oxidation or solder residue. Be cautious not to press too hard, as this may lead to damage or wear on the tip. Rotate the tip against the sponge for maximum effectiveness. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Maintaining brass cleaner is crucial for optimal performance. Regularly check for buildup of solder that may accumulate within the brass cleaning ball; replace it as necessary. The frequency of cleaning the soldering iron tip should be determined by usage. Signs that indicate it’s time for cleaning include decreased solder adherence, discoloration of the tip, and the presence of solder blobs. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

By following these steps, one can ensure efficient and effective soldering with a well-maintained soldering iron tip. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Maintaining your soldering iron and associated tools is essential for ensuring optimal performance and longevity. Proper care not only extends the life of your equipment but also improves the quality of your soldering projects. Adopting best practices in storage, handling, and routine maintenance can lead to efficient soldering outcomes. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

First and foremost, correct storage is critical. After use, always place your soldering iron in a designated holder to prevent tip damage. Ideal storage solutions such as iron stands or heat-resistant surfaces help maintain the tip’s integrity and prevent potential accidents. Additionally, ensure that the tips are cleaned appropriately after every use to eliminate any solder residue, which can lead to oxidation and reduced performance. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Handling techniques also play a key role in maintaining your soldering tools. Always hold the soldering iron by its insulated body to avoid burns and to prevent any unintentional damage to the tip. When soldering, apply a consistent temperature and avoid pressing too hard against the work surface; this can create undue stress on the soldering tip, leading to premature wear and tear. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Periodic maintenance checks are an essential practice. Regularly inspect your soldering iron for signs of wear, such as burnt or pitted tips. Replace worn tips promptly, as they can significantly affect the quality of your work. It’s also crucial to select compatible cleaning tools for different soldering alloys, as this ensures the cleaning process doesn’t inadvertently damage the tip or other components. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Incorporating these practices into your routine will ultimately lead to a significant enhancement in your soldering experience. By prolonging the life of your soldering equipment through mindful care, you can achieve consistent, high-quality results in your projects. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

In summary, selecting the appropriate soldering iron tip cleaner plays a crucial role in enhancing your soldering efficiency and effectiveness. Throughout this guide, we have explored various cleaning tools and methods available, each offering unique advantages. Whether you prefer the traditional brass wire wool, the more modern ceramic cleaning pads, or the versatility of sponges, understanding the characteristics of each tool can significantly impact your work. The correct cleaner can help maintain soldering tips in optimal condition, ensuring cleaner solder joints and prolonging the lifespan of your equipment. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Your choice ultimately depends on personal preference, the specific soldering projects you undertake, and the materials involved. For instance, certain cleaning tools may work better with lead-free solder or in applications requiring higher precision. It can be beneficial to experiment with different cleaning methods to determine which one aligns best with your style. A cleaner soldering tip contributes to improved heat transfer, and effective cleaning enhances your overall soldering experience. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Furthermore, the practice of routinely cleaning your soldering iron tip cannot be overstated; neglecting this aspect may lead to increased oxidation and poor solder quality. By taking the time to explore and trial various soldering iron tip cleaners, you’ll develop a more refined approach to your soldering projects. Ultimately, this exploration will not only yield better solder joints but also make your soldering tasks more enjoyable. Therefore, take the time to assess your needs, consider the tools discussed, and make an informed decision that will enhance your soldering endeavors. Soldering Iron Tip Cleaner Desoldering Cleaning Ball Welding Soldering Iron Mesh Filter Metal Wire Stand Steel Ball Tin Remover

Official Website : https://www.mechanichk.com/

| Weight | 0.3 kg |

|---|

Reviews

There are no reviews yet.