Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Original price was: ₹250.₹149Current price is: ₹149.

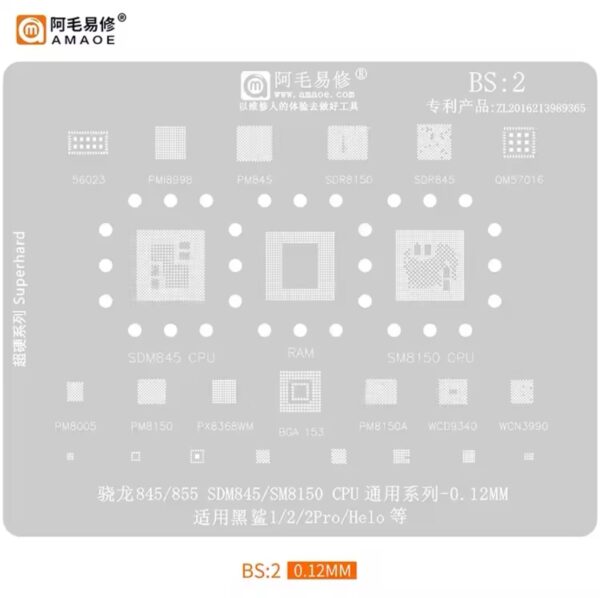

The Amaoe BS2 BGA Reballing Stencil is a paramount tool designed specifically for mobile device repair, particularly in the context of Ball Grid Array (BGA) components. Its design is meticulously crafted to cater to the precise needs of soldering processes, ensuring that each ball is accurately positioned for optimal performance. Made from high-quality materials, the stencil boasts exceptional durability, allowing it to withstand the rigors of repeated use without compromising its integrity. Amaoe BS2 BGA Reballing Stencil

One of the distinguishing characteristics of the AAMOE BS2 is its ability to facilitate the alignment of solder balls. Proper alignment is critical during the reballing process, as misalignment can lead to ineffective connections and subsequent failures in mobile devices. This stencil is engineered to ensure uniform spacing and size of balls, which are essential for achieving a reliable electrical connection. The integration of this stencil with BGA components not only enhances the repair accuracy but also contributes to the overall longevity of the mobile device. Amaoe BS2 BGA Reballing Stencil

Furthermore, using a quality reballing stencil such as the AAMOE BS2 directly influences repair efficiency. Technicians can execute the reballing process with speed and precision, minimizing errors commonly associated with manual methods. This efficiency translates into time saved and improved turnaround rates for mobile repairs. Additionally, repairing devices with this stencil yields better electrical performance, as the uniform solder balls allow for consistent conductivity across the board. Amaoe BS2 BGA Reballing Stencil

In essence, the AAMOE BS2 BGA reballing stencil stands out as an essential asset within the mobile repair industry. Its thoughtful design, choice of materials, and unique features position it favorably for technicians seeking to enhance their repair capabilities and outcomes. Amaoe BS2 BGA Reballing Stencil

Utilizing the AAMOE BS2 BGA reballing stencil involves a systematic approach that ensures high-quality repairs and improved efficiency in mobile device repair processes. To begin, preparation is crucial; start by ensuring that all necessary tools and components are readily accessible. This includes a clean work surface, a suitable solder paste, and a reliable heating source such as a hot air rework station. It is essential to work in a well-ventilated area to mitigate any risk associated with solder fumes. Amaoe BS2 BGA Reballing Stencil

Once the workspace is set, proceed with stencil placement. Align the AAMOE BS2 stencil accurately over the BGA pad to ensure uniform solder ball application. Attention to detail during this step is vital, as misalignment can lead to poor solder joints. After secure placement, apply solder paste evenly through the stencil using a squeegee. It is advisable to use consistent pressure for a uniform distribution of solder paste across the stencil openings. Following this, carefully remove the stencil to avoid smearing any solder paste. Amaoe BS2 BGA Reballing Stencil

The next step involves placing solder balls onto the applied solder paste. Gently press each solder ball onto the paste to ensure adhesion. It is recommended to use the correct size and type of solder balls compatible with the AAMOE BS2 stencil for optimal results. After the solder balls are in place, proceed to the reflow process, utilizing the appropriate temperature settings for the materials used. Amaoe BS2 BGA Reballing Stencil

One of the distinguishing characteristics of the AAMOE BS2 is its ability to facilitate the alignment of solder balls. Proper alignment is critical during the reballing process, as misalignment can lead to ineffective connections and subsequent failures in mobile devices. This stencil is engineered to ensure uniform spacing and size of balls, which are essential for achieving a reliable electrical connection. The integration of this stencil with BGA components not only enhances the repair accuracy but also contributes to the overall longevity of the mobile device. Amaoe BS2 BGA Reballing Stencil

Post-reballing inspection is critical to determine the quality of the work done. Inspect each joint for solder ball placement and signs of bridging or misalignment. Common challenges include insufficient solder coverage or misalignment; however, troubleshooting these issues often requires meticulous attention to detail and a steady hand. Ensuring a clean workspace and practicing safety precautions during this entire process will significantly contribute to achieving high-quality repairs. Amaoe BS2 BGA Reballing Stencil

One of the distinguishing characteristics of the AAMOE BS2 is its ability to facilitate the alignment of solder balls. Proper alignment is critical during the reballing process, as misalignment can lead to ineffective connections and subsequent failures in mobile devices. This stencil is engineered to ensure uniform spacing and size of balls, which are essential for achieving a reliable electrical connection. The integration of this stencil with BGA components not only enhances the repair accuracy but also contributes to the overall longevity of the mobile device. Amaoe BS2 BGA Reballing Stencil

More Products : https://gsmtoolsindia.com/

Official Website : https://www.mechanichk.com/

| Weight | 0.01 kg |

|---|

Reviews

There are no reviews yet.