Address

Office Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Shop No-01 Lucia City Center, OTC RoadNear Shardha Theater SP Road, Bangalore-560002

Work Hours

Monday to Saturda: 7AM - 7PM

Weekend: 10AM - 5PM

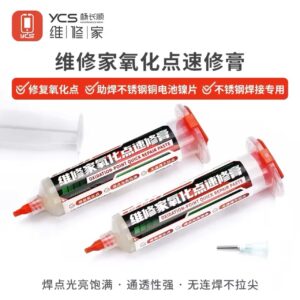

Original price was: ₹350.₹249Current price is: ₹249.

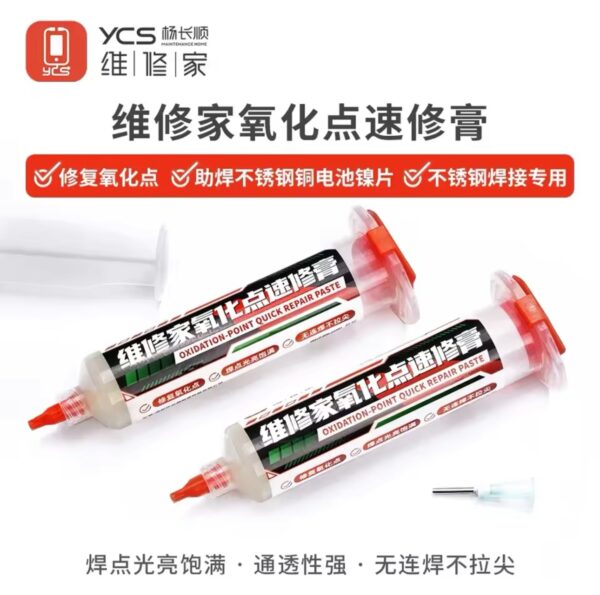

YCS 50G Solder Flux is a specially formulated compound designed to enhance the soldering experience by promoting stronger and more reliable connections. This solder flux is composed of a carefully balanced mixture of ingredients that provide critical properties such as oxidation resistance and heat stability, making it an essential tool for various soldering tasks, particularly in the realms of stainless steel, nickel, and copper.

Once the surfaces are clean and pre-tinned, applying the YCS 50G Solder Flux becomes critical. Use a brush or applicator to apply the flux uniformly onto the area to be soldered, ensuring full coverage. The next essential factor is heating the joint adequately. A controlled heating method should be utilized; both excessive and insufficient heat can lead to issues like oxidation or weak solder joints. Aim for a temperature range recommended for the specific metals you are working with to ensure that the flux activates properly.

One of the standout features of YCS 50G is its ability to function effectively across a wide temperature range, which is vital in demanding applications. Its composition allows it to engage and protect the metal surfaces during the soldering process, ensuring high-quality solder joints that are less susceptible to failure. This makes it an excellent choice for intricate soldering work in electronics and other industries where precision is paramount.

The effectiveness of YCS 50G in soldering applications is particularly evident when working with materials such as stainless steel, nickel, and copper. Stainless steel, for example, is notoriously difficult to solder due to its smooth surface and propensity for oxidation, but YCS 50G provides the necessary fluxing action to enable proper adhesion. Similarly, with nickel and copper, YCS 50G ensures that the solder penetrates the surfaces sufficiently to form strong, enduring connections.

Specific use cases for YCS 50G extend to the soldering of CPUs, integrated circuits (ICs), ball grid arrays (BGAs), and battery connections. In these applications, the right solder flux is crucial for achieving optimal joint quality and performance. YCS 50G not only simplifies the soldering process but also enhances the reliability of the final product. Therefore, understanding the characteristics and applications of YCS 50G Solder Flux is essential for anyone looking to improve their soldering outcomes.

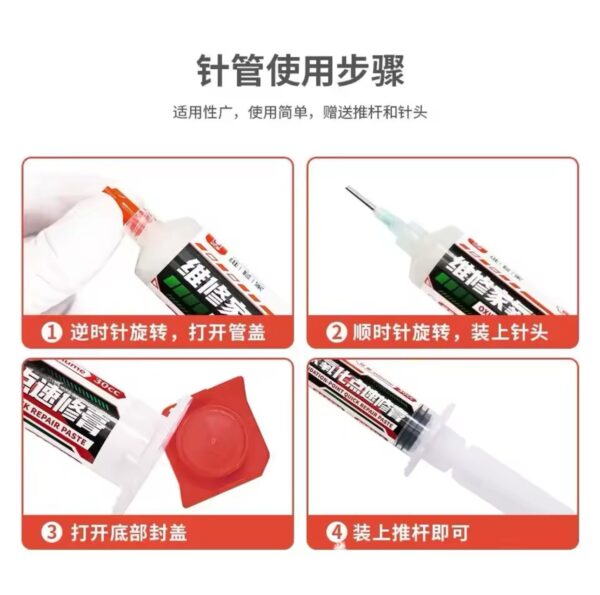

When utilizing YCS 50G Solder Flux for soldering applications involving stainless steel, nickel, and copper, adhering to several best practices can significantly enhance the quality of your work. The initial step involves thorough surface cleaning. It is essential to remove any contaminants such as oil, grease, and oxidation from the surfaces to be joined. Using a suitable solvent or abrasive material, ensure that the metallic surfaces are scrubbed clean, which will promote excellent adhesion during the soldering process. Pre-tinning components before final assembly is highly recommended, as it prepares the surfaces for optimal bonding.

Once the surfaces are clean and pre-tinned, applying the YCS 50G Solder Flux becomes critical. Use a brush or applicator to apply the flux uniformly onto the area to be soldered, ensuring full coverage. The next essential factor is heating the joint adequately. A controlled heating method should be utilized; both excessive and insufficient heat can lead to issues like oxidation or weak solder joints. Aim for a temperature range recommended for the specific metals you are working with to ensure that the flux activates properly.

During the cooling process, allow the solder joints to cool naturally. Quenching with water or subjecting the joint to rapid cooling methods can lead to stress and potential cracking. Furthermore, when using YCS 50G Solder Flux, it is vital to prioritize safety. Always wear appropriate personal protective equipment (PPE) such as gloves and goggles to safeguard against any splashes or fumes. Once your soldering project is complete, store any remaining YCS 50G Flux in a cool, dry area, making sure the container is tightly sealed to prevent contamination and maintain efficacy. By following these best practices, users can maximize both the efficiency and safety of their soldering processes.

More Products : https://gsmtoolsindia.com/

Official Website : https://www.mechanichk.com/

| Weight | 0.056 kg |

|---|

Reviews

There are no reviews yet.